In 1972 and in those years, Datsun, Lancia and even Porches were commonly seen at the starting line of FIA International Championship for Manufacturers to try to win the honors.

But no one expected to see a 5,000-pound 4×4 monster with its name written on the side: MOBY DICK I.

A man named Gene Henderson believed he could win with that 4×4 white whale. The driver wasn’t a beginner in car racing, holding a nice list of prizes. He won the 1963 Press on Regardless Pro Rally, finished fifth at the 1964 Monte Carlo Rally, won 10 of 12 National SCCA races in 1967, won at Monte Carlo, and won the Shell 4000 in 1968.

He believed it was possible to drive the rig to victory. Let’s not forget, the vehicle wasn’t ordinary, it was equipped with a Quadra-Trac system (4×4) which wasn’t common at all in car rallying. From the moment the vehicle was chosen, there was a very short window – about 2 months – to prepare the rig for that type of racing. Although the V-8 developed about 400hp and provided sufficient power, the problem was more around road handling and rebound when the vehicle hit bumps or any other obstacles, making it hard for the driver to keep it in control and save precious seconds.

The problem was fixed with the help of suspension manufacturer Monroe to optimize a suspension system better suited to this nearly 5,000-pound vehicle.

The two Wagoneers that had been prepared did their first race at the local Moonlight Monte Rally. They clashed in the service park beside Datsun 510, Volvo 240z, Ford Escort and even BMW 202. Many competitors joked about these two white elephants in the room. However, when they finished fifth and sixth, people quickly stopped making jokes and a lot of questions and surprise arose in competitors’ minds.

Although the white beast was much heavier than the other vehicles, a major asset came to play in its favour: an exceptional driver with his very personal way of driving.

Even if Henderson didn’t win this time around, the Jeep equipped with the Quadra-Tech system developed by Borg-Warner managed to do well. The team was satisfied with the results; after all they competed against nearly 80 vehicles and world-class drivers such as Europe rally champion Harry Kallstrom in over 300 stage miles of which most were run at night.

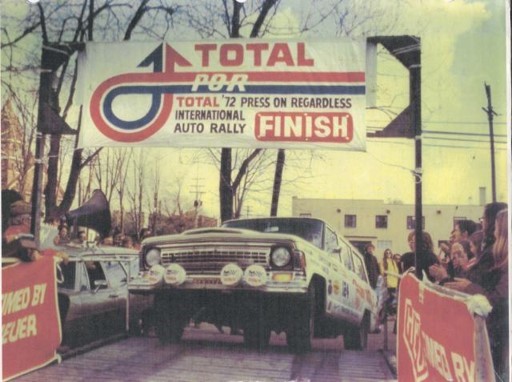

But in 1972, with a near perfect driving, even including a quick courtesy stop to check that another team stopped by the road was okay, Henderson arrived first at the finish line. Although the victory meant a lot and was a reason to celebrate for Henderson and Jeep, the event created a scandal and indignation for many.

It was said that the 4×4 system was an unfair advantage and even that the vehicle went against the spirit of rallies. This is probably why the FIA implemented a new rule in April 1973 banning 4×4 systems in vehicles taking part in their rallies.

But many European teams had seen what had happened, had paid attention to details, and had noted that 4-wheel drive wasn’t banned in SCCA Pro Rally. So there was a lot of development after that.

Later, Audi and Porche won honours with AWD system, but Jeep did it first.

Mr. Henderson was inducted into the Michigan Motorsports Hall of Fame.

Dave Daneault